Triangular oscillator - PWM square wave signal - III part

This article is dedicated to the second modulation related

to the VF driver revision 1.0. Pulse width modulation (short PWM) is the method

of the signal pulse width changes in order to control rotation speed of the DC

motor shaft. This article will explain measurements taken by the oscilloscope,

frequencemetre and voltmeter in order to present PWM signal modulation.

VF driver revision 1.0 measurements

This part will explain video clip related to the VF driver

revision 1.0 measurements taken by the oscilloscope, frequencemeter and

voltmeter in order to present pulse width signal modulation. This video is

split into the two parts: the first part is related to the frequency modulation

and the second is related to the PWM signal modulation.

Video: VF driver revision 1.0 measurements

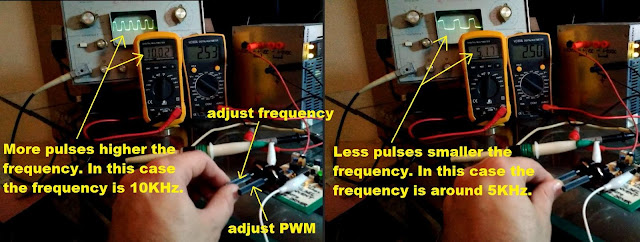

Frequency measurements

Frequency is already explained under the previous article

(II part), in this example the frequency is changed by changing variable

resistor resistance (variable resistor is implemented with potentiometer

configured as a variable resistor, for details take a look under VF driver revision 1.0 specification). As you can see from the first 1 minute and 30

seconds of the video clip, by changing the resistance of the R2 resistor

frequency are changed accordingly. The signal is presented by the oscilloscope

and frequencemetre (left digital multimeter), greater frequency is presented

with more pulses on the oscilloscope screen, while smaller frequency is presented

with less pulses on the oscilloscope screen, at the same time frequencemetre

show generated frequency (Figure #1).

|

| Figure #1: Frequency measurement - VF driver revision 1.0 |

We already have had a discussion about the frequency, it is

the signal modulation which allows us to find the right frequency of the chosen

DC motor. When right frequency has been found, it is not possible to change it

anymore. If we do need speed control related to the DC motor shaft, second

modulation must be implemented, which lead electrical schematic changes from

the previous article by adding additional comparator (without hysteresis). This

comparator is presented on the Figure #2 and it is consisted of the operational

amplifier (3) and potentiometer P2 related to voltage reference changes. Noninverting

input of the operational amplifier (3) is connected to the triangular signal of

the free-running triangular oscillator circuit, while inverting input of the

operational amplifier (3) is connected to the voltage reference point generated

by the potentiometer P2.

|

| Figure #2: Square wave generator with pulse width modulation - comparator without hysteresis (operational amplifier (3)) |

How PWM square wave signal generator work?

The Figure #3 presents how PWM square wave signal generator

work. There are four cases.

| ||

| Figure #3: PWM signal in comparison to the triangular signal and the Vref point |

First case (Figure #3.a): The voltage reference Vref (signal marked with point 3) is generated by the potentiometer P2 (Figure #2), triangular signal is connected to the noninverting high impedance input of the operational amplifier (3). When triangular signal becomes greater than the Vref voltage reference, the output of the operational amplifier (3) goes from the low signal level (~0 volts) to the ~Vcc voltage (depends on chosen operational amplifier – rail-to-rail operational amplifier = Vcc). When triangular signal becomes lower than the Vref voltage reference, the output of the operational amplifier (3) goes from the high signal (~Vcc) to the low signal lever (~0). The width of the signal is determined by the Vref point value on the Y axis on the diagrams

Second case (Figure #3.b): it is the same explanation as in

the first case, but in this case Vref point is greater in comparison to the

first case. What does that mean? That means that the pulse width will be

smaller in a second case in comparison to the first case, as it is presented

on the Figure #3.b. Now it is clear, if we do change the value of the Vref

voltage point reference, different width of the signal pulse will be generated.

The pulse width of the signal is directly reflected to the voltage value used

to drive DC motors.

Third case (Figure #3.c): it is the same explanation as in

the first case, except that in this case the Vref point reference is set above

the highest triangular signal point. That means that the PWM square wave signal

is not generated and it is zero voltage at the operation amplifier (3) output.

In this case the DC motor shaft is stopped.

Fourth case (Figure #3.d): it is the same explanation as in

the first case, except that in this case the Vref point reference is set below

the lowest potential point of the triangular signal. That means that triangular

signal is always greater than Vref which lead to the ~Vcc output of the operational

amplifier (3). In this case pulse of the signal does not exist and DC motor is

driven by the maximum power supply voltage.

PWM measurements

PWM measurements are based on voltage measurements taken by

the digital multimeter VC830L. As we can see starting from the 1 minute and 30

seconds (video clip), by changing Vref point reference with the potentiometer P2 the width

of the signal pulse are changed accordingly. When the signal width gets wider

the more voltage value is measured by the VC830L digital multimeter and vice

versa. Three different measured voltages are presented in Figure #4, and as you

can see, for small pulse width smaller voltage value is generated, and vice

versa.

|

| Figure #4: PWM signal measurements |

This generated voltage value is directly

reflected on the speed of the DC motor shaft - higher the generated PWM voltage -> faster DC motor shaft rotation, and vice versa. That doesn’t mean that

square wave signal with pulse width modulation is directly used to drive DC

motors since VF driver does not have appropriate power to run it. Instead, VF

driver is used to drive a DC motor by providing control signal pulses to the DC

motor controller/driver (like it is SERPENT I or SERPENT II), with responsibility to provide enough current amplification

to driver DC motors.

Related articles:

Triangular oscillator - Fundamentals - I part

Triangular oscillator - Frequency - II part

Triangluar oscillator - Operational amplifier slew rate - IV part

SERPENT I - DC motor controller

SERPENT I - PCB DIY (do it yourself) assembling - video clips examples

SERPENT II - Pit VIPER Rattle - DC motor controller/driver

How to design LM324 Astable Multivibrator

How to build do it yourself printed circuit board (DIY PCB) by using thermal transfer method

Programmable autonomous vehicles – Fundamentals, Part I

Power switch as current amplifier

How to design voltage reference by limiting current consumption

Fake VC830L digital multimeter

Low pass filter and voltage stabilization

zilsel-invent assumes no responsibility or liability for any errors or inaccuracies that may appear in the present document. Specification and information contained in the present schematics are subject to change at any time without notice.

Triangular oscillator - Fundamentals - I part

Triangular oscillator - Frequency - II part

Triangluar oscillator - Operational amplifier slew rate - IV part

SERPENT I - DC motor controller

SERPENT I - PCB DIY (do it yourself) assembling - video clips examples

SERPENT II - Pit VIPER Rattle - DC motor controller/driver

How to design LM324 Astable Multivibrator

How to build do it yourself printed circuit board (DIY PCB) by using thermal transfer method

Programmable autonomous vehicles – Fundamentals, Part I

Power switch as current amplifier

How to design voltage reference by limiting current consumption

Fake VC830L digital multimeter

Low pass filter and voltage stabilization

zilsel-invent assumes no responsibility or liability for any errors or inaccuracies that may appear in the present document. Specification and information contained in the present schematics are subject to change at any time without notice.

Comments

Post a Comment